Everyone wants their brand to attract more consumers’ attention among many packaged products.

Packaging technology is a very important part of packaging design. Today I will share with you 6 common printing processes.

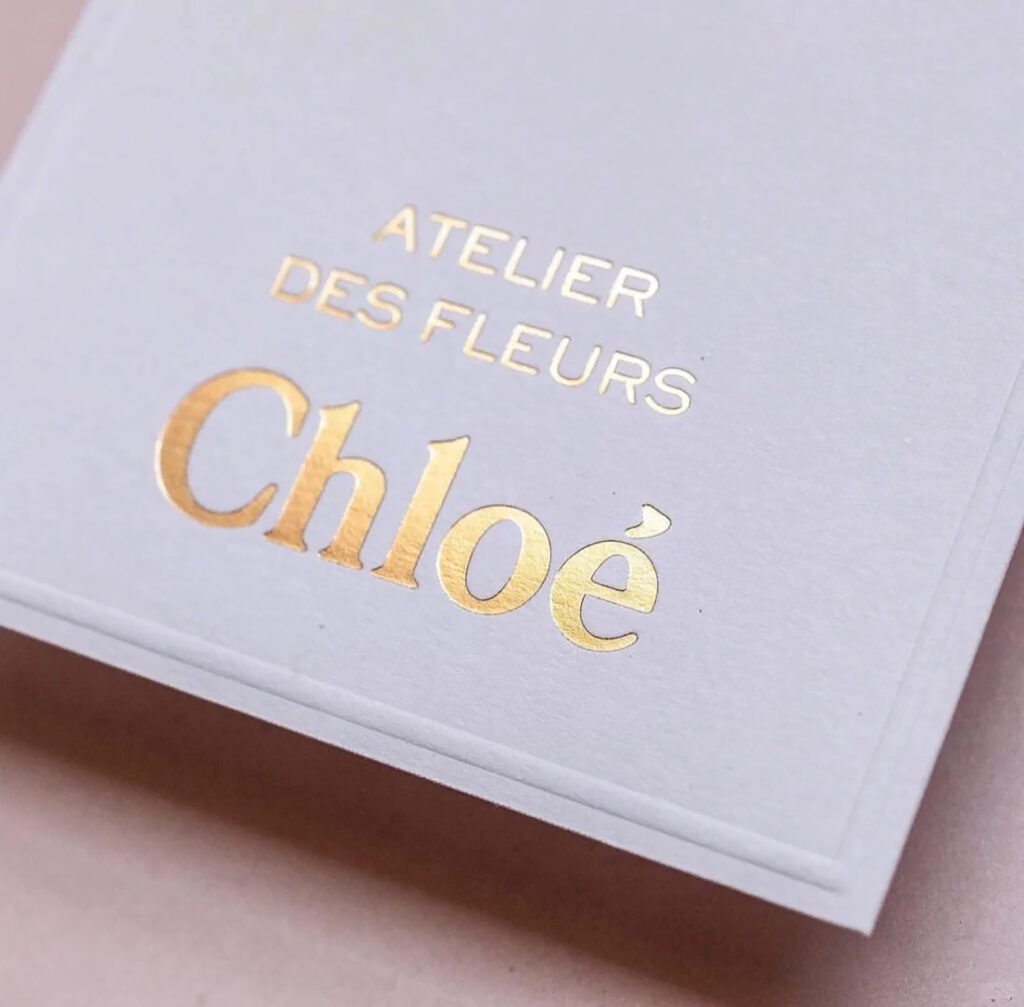

1、Hot stamping

Hot stamping is a process of hot stamping anodized aluminum foil on a substrate at a certain temperature and pressure, commonly known as “hot stamping” or “hot stamping”.

The metallic luster of hot stamping has a strong decorative effect and a strong visual impact. Hot stamping is often used in small areas, such as logos, brand names, etc., which can highlight the key points and improve the grade.

2、Local UV

Local UV is a process that uses ultraviolet light to cure the local varnish on the substrate to form a local bright effect. This process makes the printed product partially present higher brightness, transparency and wear resistance.

It can make the surface of the printed product more textured and three-dimensional, and highlight the visual effect of local bright light.

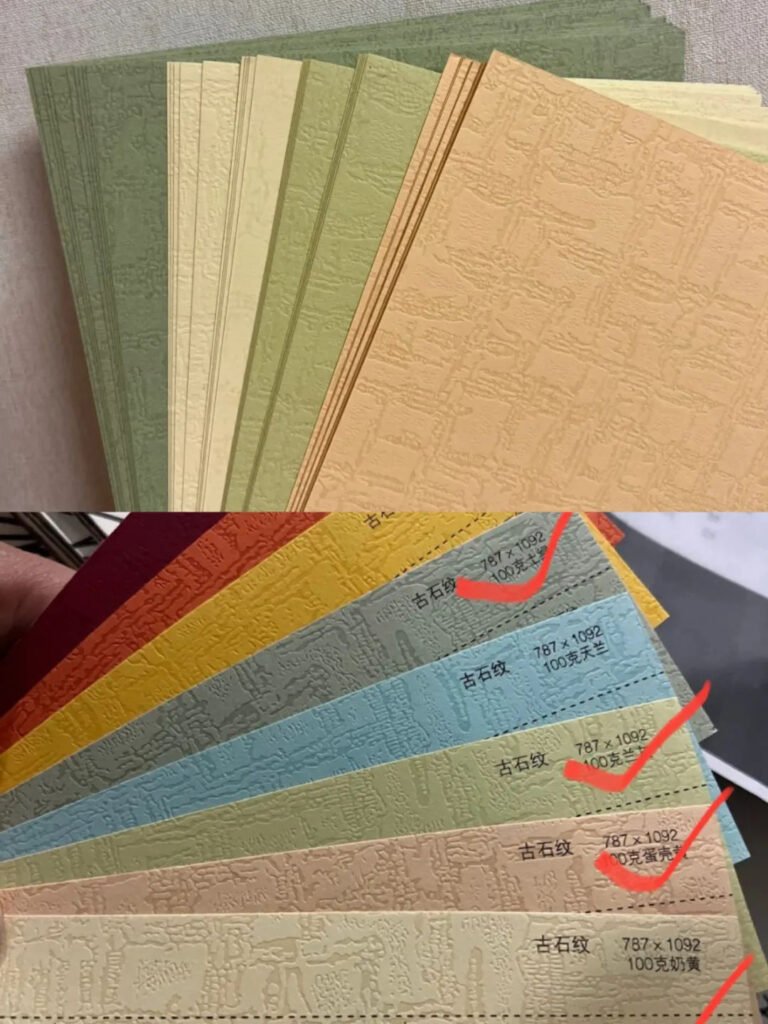

3、Embossed

Embossing refers to the presentation of different patterns and textures on the surface of the material, with a distinct texture, which makes the material change into another performance effect.

This effect will make our products more textured. If you like simple and high-end packaging products, you can choose to use embossing to achieve it. Embossing is divided into full-page embossing and partial embossing, or double-sided embossing and single-sided embossing.

Each effect is different. We can choose the effect that suits our products.

4、Embossing and Debossing

Embossing is a special process that uses a metal embossing mold to mechanically apply pressure that exceeds the elastic limit of the printed substrate to perform artistic processing on the surface of the printed product.

According to the different directions of the embossing, it can be divided into “embossing” and “debossing”. Whether it is embossing or debossing, it is a good choice for some products that want simple and advanced packaging.

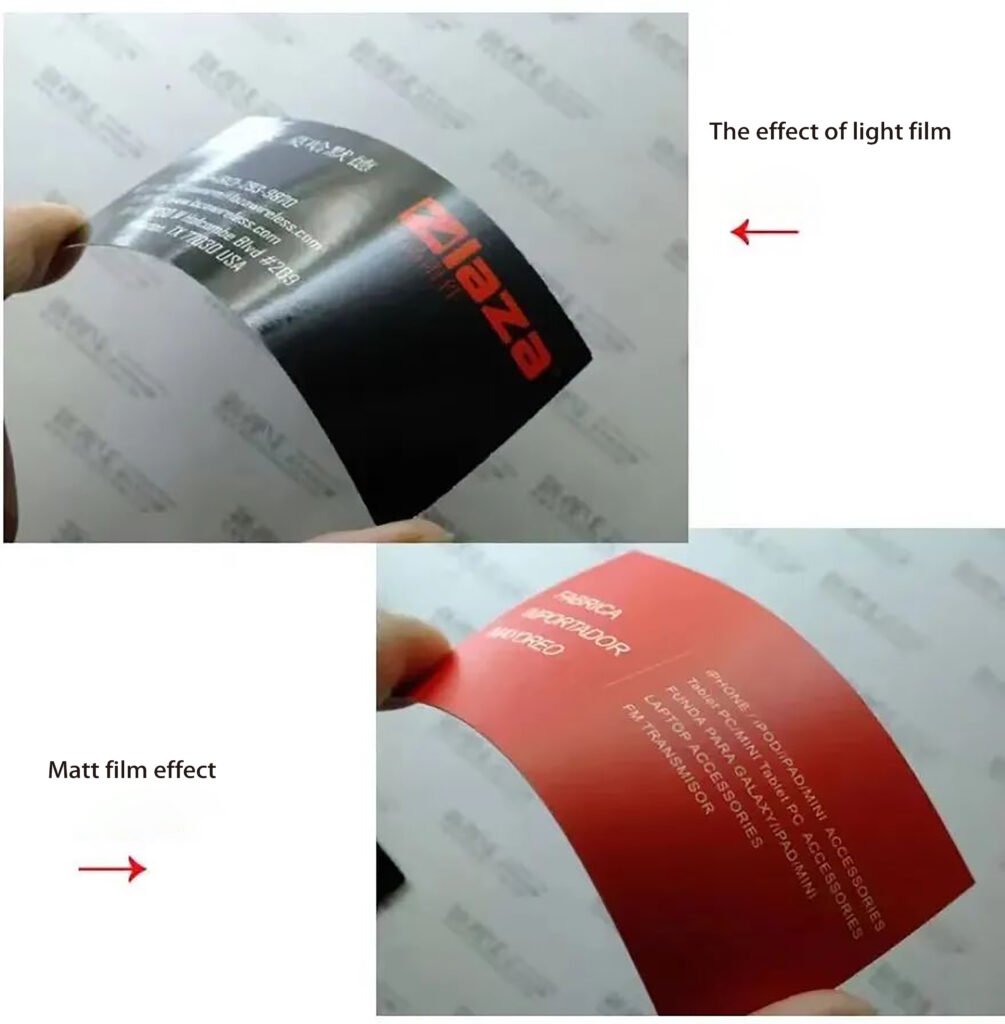

5、Lamination

Lamination refers to the process of heating, pressurizing, cooling, etc. a transparent plastic film coated with adhesive and a paper-based printed product to cover the surface of the printed product with a layer of transparent plastic film, forming a post-printing processing technology that combines paper and plastic.

There are two types of lamination, one is matte film and the other is glossy film.

They have different effects on packaging. The glossy film looks reflective, while the matte film gives a high-end effect.