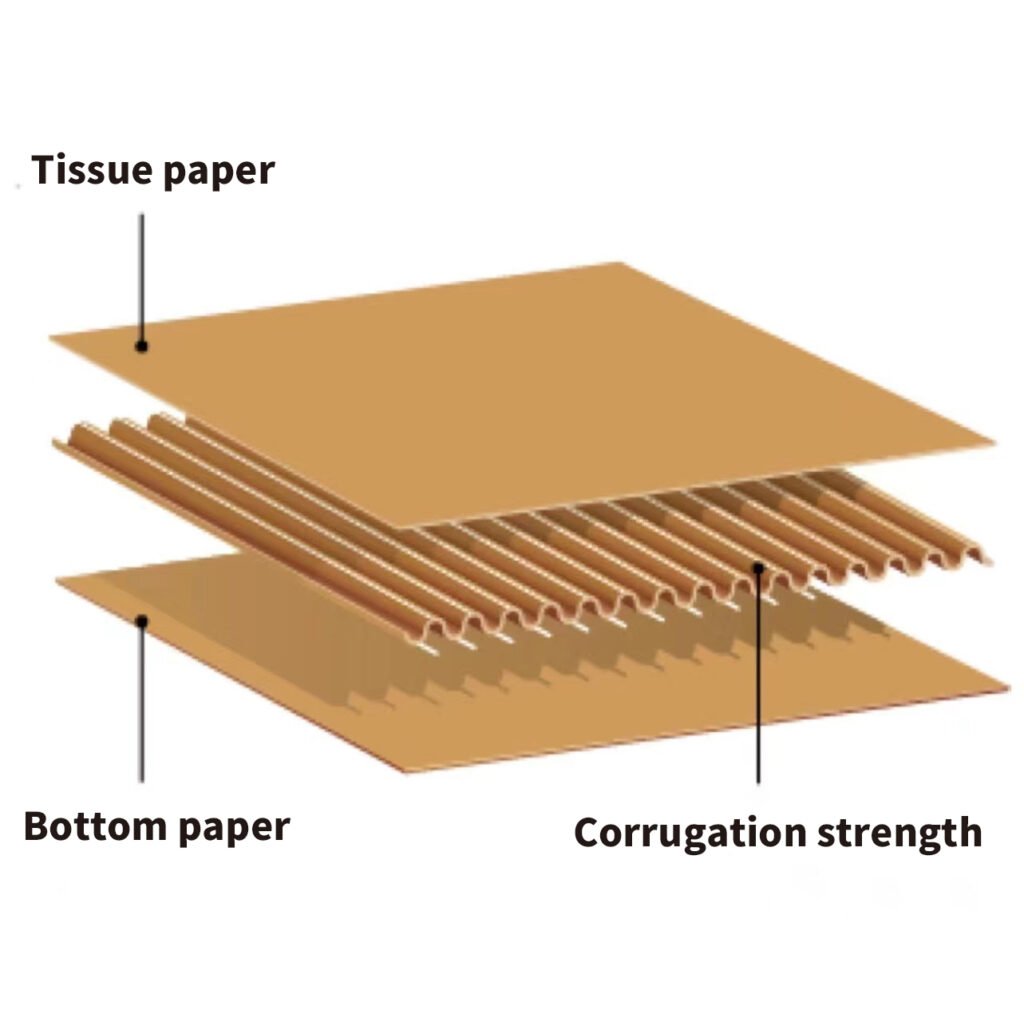

Corrugated transport boxes are made of corrugated cardboard that is processed and formed into a three-dimensional carton. Corrugated cardboard is a sturdy packaging material. The outer layer is called the face paper, the wavy layer is called the core paper or corrugated paper, and the bottom layer is called the lining paper. Now this kind of corrugated transport box is used as a courier box by e-commerce sellers, because it can not only be formed in one piece, but also has the function of cushioning and shock absorption to protect the goods and facilitate transportation, and it also plays the role of beautifying and promoting the products.

1、Lightweight and with high load-bearing capacity

The load-bearing capacity of corrugated paper comes from its corrugated structure. The folding structure of the corrugated shape makes the corrugated board have better compression resistance under pressure. At the same time, due to the arc shape of the corrugated paper, it also has good bending resistance.

Corrugated corrugation also has different specifications, which we call flute type. The national standard divides the flute type into type A, type B, type C, type E, and type F according to the flute height, flute width and the number of flutes per 300mm. Type A corrugated and type B corrugated are generally used as outer packaging boxes for transportation. Type E is mostly used as a single-piece packaging box with certain aesthetic requirements and for placing appropriate weight contents. In a double corrugated box, two different flute types are used to make the box have a higher load-bearing capacity and better compression resistance.

Of course, the load-bearing capacity of a corrugated box depends on many factors, such as the density of the paper, the material of the face paper and the back paper, the flute structure of the corrugated, the way the box is joined, and the box type of the box.

2、Use Fsc recyclable materials

The raw materials of corrugated boxes are mainly kraft paper, corrugated base paper, white cardboard, etc. The production of these raw materials can use recycled paper. The production of corrugated base paper has achieved 100% recycled paper recycling, which improves the utilization rate of resources. Recyclable corrugated boxes make it greener in the product life cycle compared to other plastic packaging products, and there is no need to worry about polluting the environment.

3、Tailored to Your Needs

Whether for electronics, cosmetics, homeware, or food products, we design custom box shapes and printing solutions based on your product size, weight, and shipping requirements—transforming packaging into a powerful brand ambassador.

Flexible and convenient, foldable

The Master of Space Management:The foldable corrugated box breaks the limitations of traditional fixed – shape packaging. It can be quickly folded into a thin sheet when not in use, saving a significant amount of storage space. During transportation, it can also be flexibly stored, reducing the volume of empty loads and optimizing logistics costs. It is truly a smart choice for space utilization.