The Ultimate Guide to Choosing Paper for Color Boxes: Find the Perfect Match for Your Product

Selecting the right paper for your color boxes is critical. It impacts product protection, visual appeal, brand perception, and environmental footprint. Different paper stocks offer unique properties suited to specific needs.

Here is a detailed explanation of common color box paper types:

1、Paper Card

Key Characteristics: Sturdy, rigid structure providing good basic load-bearing capacity.

Advantages: Cost-effective, excellent printability, ideal for high-volume production.

Considerations: Limited water/moisture resistance.

Ideal Applications: Electronics, cosmetics, pharmaceuticals, lightweight consumer goods.

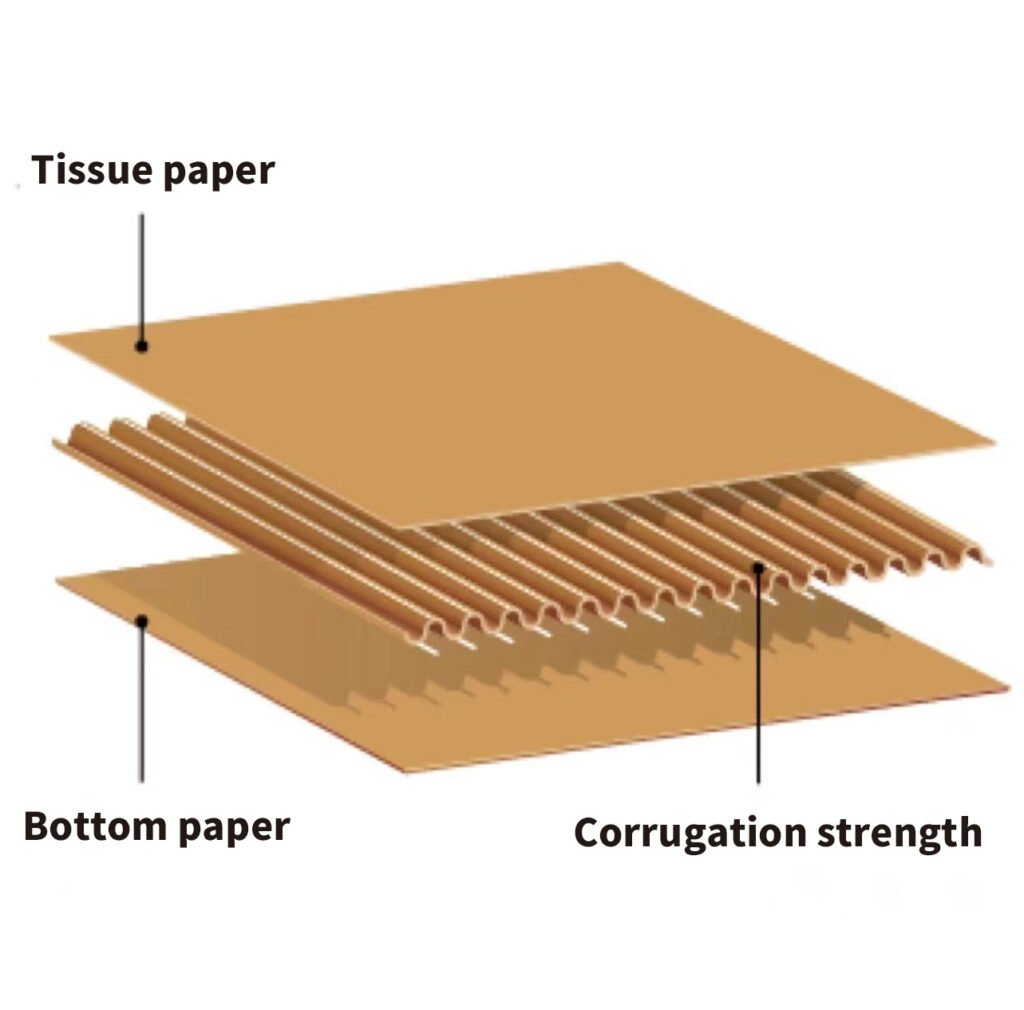

2. Corrugated cardboard

Key Characteristics: Multi-layered with fluted core, offering superior cushioning and compression resistance.

Advantages: Exceptional protection for heavy or fragile items, high cost efficiency for shipping.

Considerations: Surface smoothness is lower; lamination or specialized printing is often needed for high-end visuals.

Ideal Applications: Appliances, hardware, logistics/shipping boxes, e-commerce fulfillment.

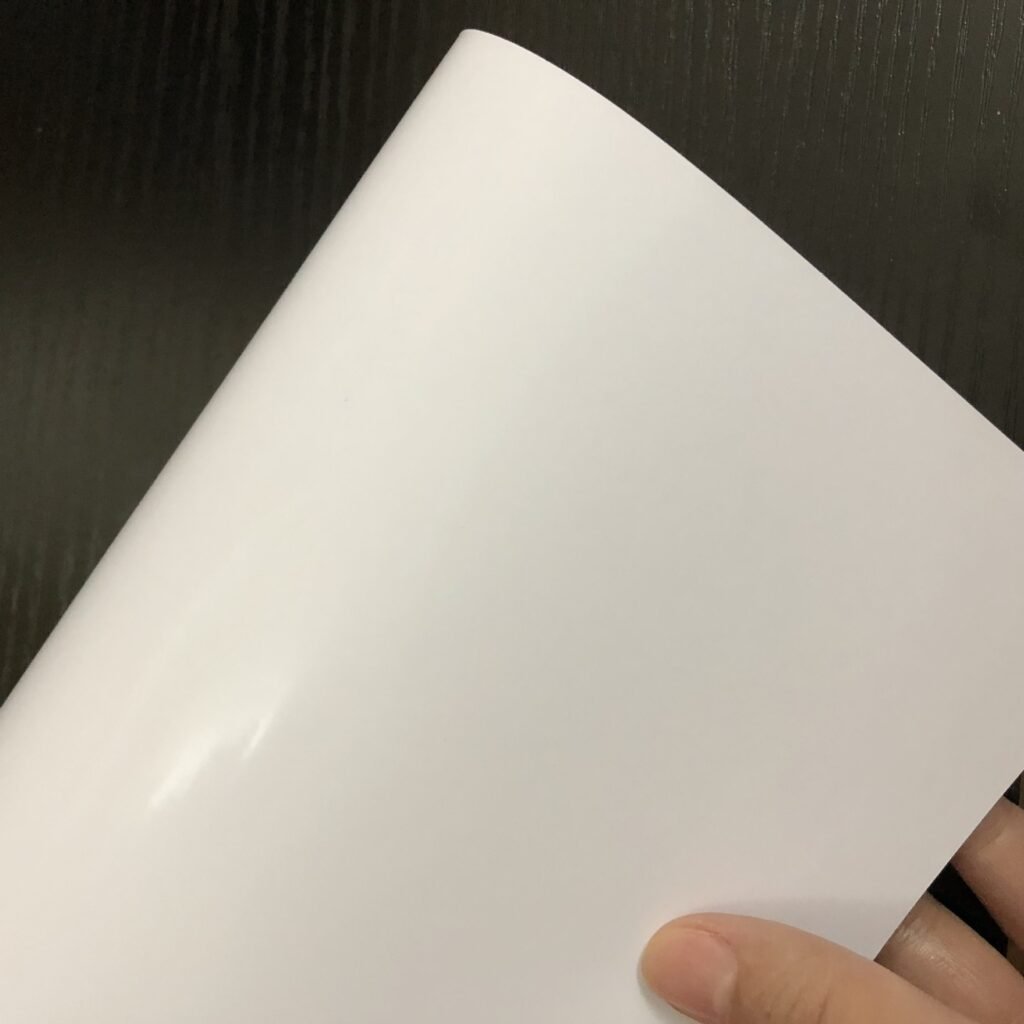

3. Art Paper (Single/Double Sided Coated)

Key Characteristics: Coated surface. Single-sided: one side gloss/matte; Double-sided: high gloss both sides. Delivers premium print results.

Advantages: Vibrant color reproduction, high image detail, significantly elevates perceived product value.

Considerations: Higher cost, lower folding endurance compared to uncoated boards.

Ideal Applications: Luxury gifts, premium cosmetics, high-end food packaging, brochure covers.

4. Grey Board

Key Characteristics: Thick, dense, and very rigid, commonly used as the base for premium rigid boxes.

Advantages: Outstanding load-bearing capacity, excellent for complex structures (e.g., book-style, drawer boxes) & finishing (foiling, UV).

Considerations: Raw appearance is utilitarian; requires covering paper or sophisticated surface finishing.

Ideal Applications: Jewelry, watches, premium tea/coffee, spirits, luxury goods packaging.

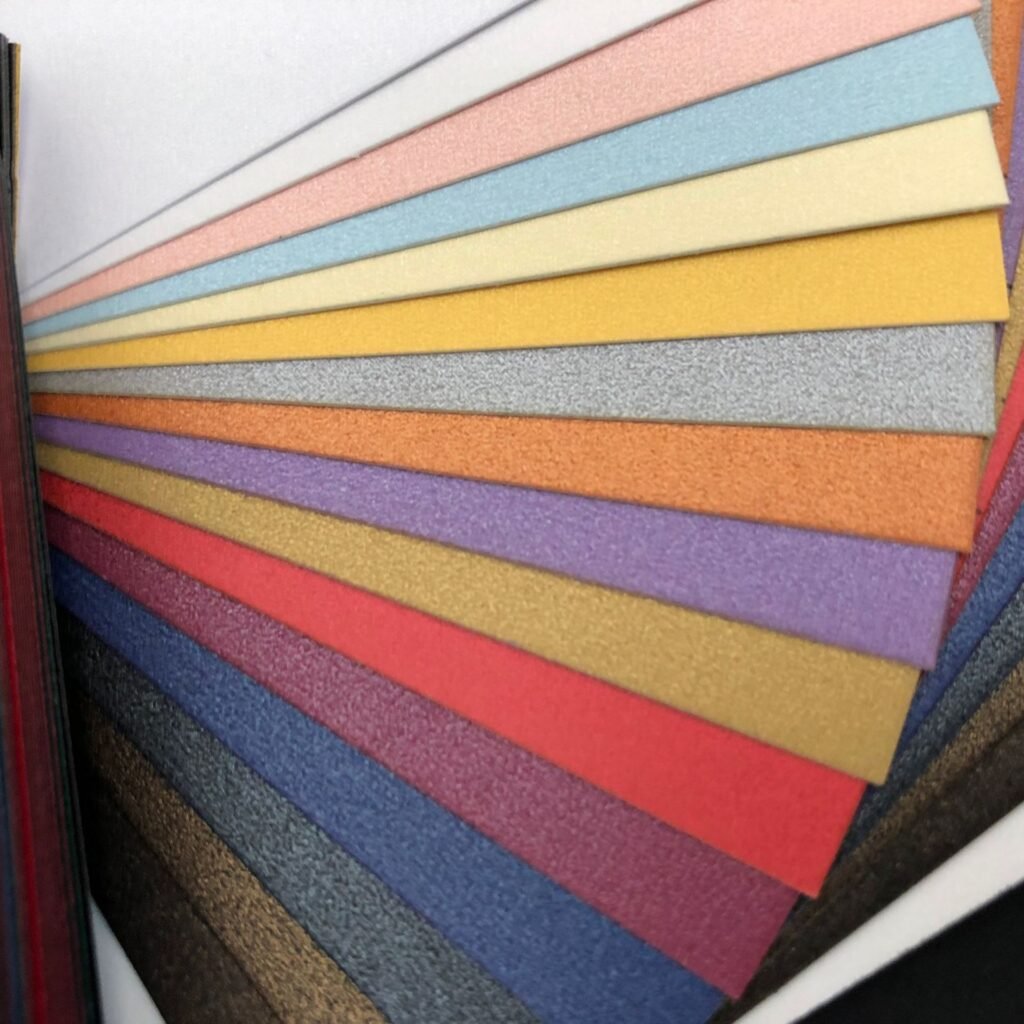

5. Specialty Paper

Key Characteristics: Wide variety (e.g., metallic, pearlescent, textured, recycled art papers) offering unique tactile & visual effects.

Advantages: Creates strong differentiation and premium feel, enhances brand identity.

Considerations: Typically higher cost, may require specialized printing and converting processes.

Ideal Applications: Luxury goods, limited editions, high-end cosmetics, art/collectibles packaging.

6. Eco-Friendly Paper

Key Characteristics: Made from recycled content, FSC-certified virgin fibers, or sustainable alternatives like bagasse or bamboo pulp.

Advantages: Significantly reduces environmental impact, aligns with ESG goals and consumer demand for sustainability.

Considerations: Physical properties (strength, water resistance) may be slightly lower than standard papers; verify specifications.

Ideal Applications: Organic food, natural health products, eco-conscious brands, sustainability-focused companies.

Key Selection Considerations

- Define Requirements: Prioritize product characteristics (weight, fragility), protection needs, brand positioning (luxury/mass market), budget, and critically – SUSTAINABILITY GOALS.

- Visual Impact: For stunning print and premium feel, choose Art Paper or Specialty Paper. Corrugated prioritizes protection.

- Protection: Opt for Corrugated Board for heavy or fragile items. Cardboard and Grey Board suit light-to-medium weight products needing structure.

- Sustainability: Eco-Friendly Paper is a strategic choice to demonstrate responsibility. Certifications like FSC are highly valued in EU/US markets.

- Functionality: Consider window patching with clear PET or PVC for product visibility if needed.

- Consult Experts: When unsure of the optimal material or balancing complex requirements, leverage your packaging supplier’s expertise.

Choosing the right paper is the foundation of successful packContact usaging!